Oil & Gas services

“Smart decision making, always requires a closer look”

Norse Asset solutions was founded in 2017 to handle the ever so growing demand for high technological and quality equipment in a diverse industry field ranging from government and military to private industry clients.

Higher industry requirements fueled by growing challenges requires a shift in risk-based evaluation and more detailed focus in data acquirement and aggregation.

Our personnel consist of highly skilled and experienced employees from a diverse background giving us the edge and tools necessary to handle even the highest demanding challenges put forward by our clients and industry application.

A company`s strongest point is its employees and one of our strong foundations is our focus on general safety and well being within our team enabling higher focus and quality.

Make it stand out!

By using our technique, we remove up to 80% of the noise created by water particles in the air, this and our IP67 graded equipment enable us to carry out inspections even in demanding weather conditions!

Using SW and knowledge.

Using software tools to rapidly process raw footage from field combined with over 20y of field inspection experience has enabled us to develop a RBI technique and method saving our client valuable time and cutting cost in asset management.

Our company have vast operational experience from all parts of installation design, build, commissioning, operation and P&A.

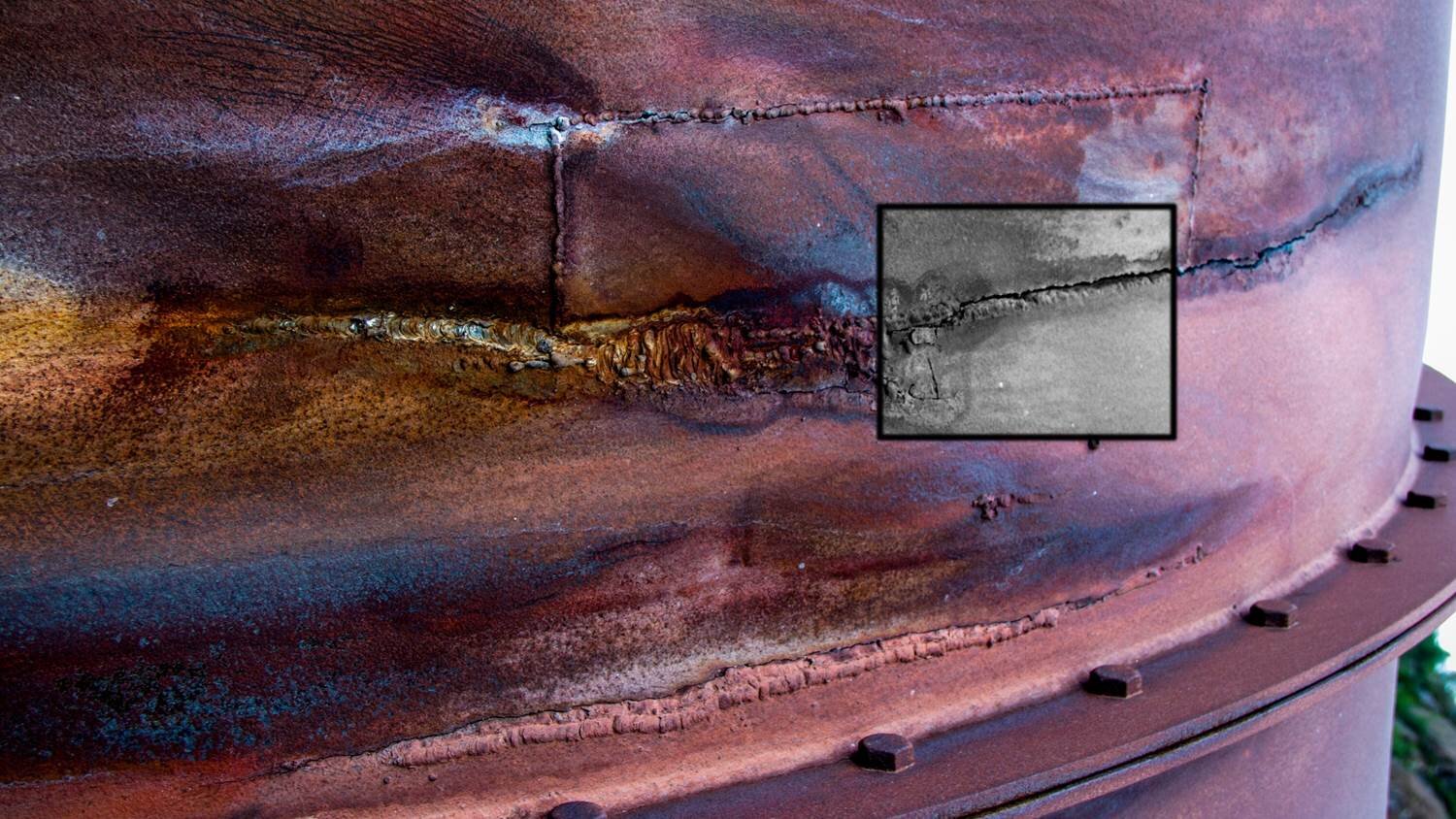

Zoom in.

Close Visual Inspection is not about taking a close up image of a structure.

We have equipment that exceeds the optical zoom and the necessary pixel rate to collect the required image resolution needed to see all crucial defects in a structure.

This also enable us to always keep a safe distance from the inspected surface, this is especially crucial in offshore installation operation and/or demanding weather conditions.

Report it.

It is all about capturing the right defect from the right angle to be able to make the right decision at the right time and to make a professional assessment of the defect based on structural analysis, design spec, tolerances, life in service and RBI program.

Using our workflow the client gets a fully written report including all uncovered defects and assessment of the structure by certified professionals.

Our zoom capabilities

The video shows our zoom capabilities using our high spec unmanned aerial inspection drones.

Oil and gas services

Visual Inspection Services

-Derrick structural inspection

-Dropped objects assessment

-Flare tip and tower inspection

-Condeep inspection

-Under rig corrosion and moon pool inspection

-Splash zone assessment

Contact us for options

Digitization and Digital Twin

We work both topside and sub-sea!

-Laser scanning with sub mm resolution and accuracy

-Photogrammetry with sub 3mm resolution and accuracy

-Site-visits and 3D modeling for engineering/tender purposes in as built environment

-Establishment or updating As built models.

- Fitment/ clash-testing in as built 3D data.

Contact us for options

Making use of the Digital Twin

Scan it.

We use the newest available high detail 3D scanners to collect and develop a high accuracy 3D model of your asset.

Check it.

Using our tools and method we import your CAD models directly into one and the same software, housing the 3D Digital Twin.

Merge it.

Merging CAD with the digital twin we are able to conduct several analyses; Clash tests, As-Built tolerance checks and QC, updating As built CAD and more.

Modification planning.

Why not use the Digital Twin as a planning tool for modification work or as a documentation basis for supplier tenders?

Are you planning to do modification work at one of you sites?

In that case we can establish a model containing 2D CAD, 3D CAD, 3D laser scan, documentation (e.g. excel, PDF, word) and more in one working model.

We can from here work with you on establishing scope of work, detailing effected structure, what needs to be moved/ modified to fit new structural parts or machinery and even simulate the job digitally.

By using this method you will save unnecessary cost, limiting downtime and severely raise you HSE and work related situation awareness.

Contact us for options

Plant Floor Flatness.

We conduct floor flatness analysis using new or excising

3D models.

Live Modelling.

We can model and extract directly in a 3D scans for further analysis in CAD tools.

Adding Images.

We add Geo-referenced inspection imagery directly to the 3D model to make it all easy for the client.

Concrete Inspection

Through our sister company we have developed a new and cutting edge

NON-DESTRUCTIVE concrete inspection tool.

The tool enable us to see through concrete to measure top-layer with mm accuracy.

It also enable us to produce as built documentation of steel rebar structure and indicate level of uncovered corrosion in rebars.

Adding the level and depth of chlorides gathered from boreholes we can safely and non destructively give the client a detailed “map” of the concrete structure and condition.

Contact us for options

Contact us.

Fill inn your information and

one of us will contact you shortly.